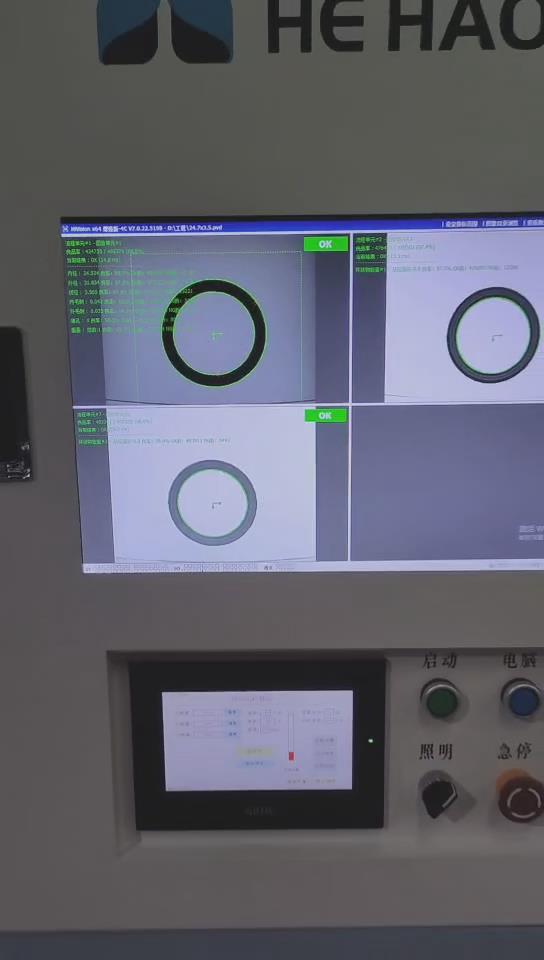

O-ring quality testing machine

With the continuous development of modern society, our company is moving towards the era of high-tech, contactless, automated and intelligent development. Machine vision technology is increasingly used in various industries. It can also be seen in the inspection of various products in the rubber parts industry such as O-rings and sealing rings. Machine vision…

With the continuous development of modern society, our company is moving towards the era of high-tech, contactless, automated and intelligent development. Machine vision technology is increasingly used in various industries.

It can also be seen in the inspection of various products in the rubber parts industry such as O-rings and sealing rings. Machine vision inspection uses automated machines to replace human eyes and brains for judgment, measurement and identification.

The characteristics of the O-ring production line are high speed, non-contact, high precision, etc. The application of machine vision technology in the rubber industry mainly includes the following aspects:

1. Appearance defect detection

Appearance quality inspection is to meet the need for product appearance quality control. The system uses self-developed core algorithms such as surface defect detection, color measurement, and rapid modeling, and has good detection results for special defects such as cracks, streaks, crushing, and dirt. Through the combination of system modules, it can meet the detection requirements of mid-to-high-end users for various precision O-rings.

2. Dimensions

O-ring optical inspection equipment can not only detect surface defects, but also easily detect dimensions, such as height, thickness, inner and outer diameter, diameter, etc., effectively reducing worker labor intensity and improving O-ring quality.

Technical features of the O-ring rubber seal detection and screening machine we use

1. High technical content, advanced technology, high precision, good stability, reliable quality and easy operation.

2. Stable and accurate during the detection process, without vibration, impact and other adverse phenomena.

3. The data is displayed and automatically judged as “good product” or “defective product”.

4. Using German CCD high-resolution cameras, the quality and reliability are very good.

5. It can be equipped with automatic conveying device and automatic assembly device to complete automatic loading and unloading of materials.