How much do you know about O-rings?

O-ring rubber ring, referred to as O-ring, is a rubber ring with a circular cross-section. O-rings are the most widely used seals in hydraulic and pneumatic systems. O-rings have good sealing performance and can be used for both static seals and dynamic seals. They can not only be used alone, but are also a basic…

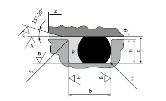

- O-ring rubber ring, referred to as O-ring, is a rubber ring with a circular cross-section. O-rings are the most widely used seals in hydraulic and pneumatic systems. O-rings have good sealing performance and can be used for both static seals and dynamic seals. They can not only be used alone, but are also a basic component of many combined sealing devices. It has a wide range of uses and can meet the requirements of various media and various sports conditions if the material is properly selected.The O-ring is an extrusion seal. The basic working principle of the extrusion seal is to rely on the elastic deformation of the seal to cause contact pressure on the sealing contact surface. If the contact pressure is greater than the internal pressure of the sealed medium, there will be no leakage, otherwise leakage occurs.

- The O -type sealing ring is a typical squeezing seal. The compression rate and stretch of the diameter of the O -type cross section are the main content of the seal design, which is of great significance to the sealing performance and service life. The O -sealing ring has a good sealing effect to a large extent depends on the correct matching of the size of the O -type circle and the size of the groove, forming a reasonable sealing circle compression and stretching amount.

- The compression ratio W is usually expressed by the following formula:W=(d0-h)/d0×100%

In the formula, d0—–the cross-sectional diameter of the O-ring in the free state (mm);

h——The distance between the bottom of the O-ring groove and the sealed surface (groove depth), that is, the cross-sectional height of the O-ring after compression (mm)

When selecting the compression ratio of the O-ring, the following three aspects should be considered:

1. There must be sufficient sealing contact area;

2. Friction should be as small as possible;

3. Try to avoid permanent deformation.

From the above factors, it is not difficult to find that they are contradictory to each other. A large compression ratio can obtain a large contact pressure, but an excessive compression ratio will undoubtedly increase sliding friction and permanent deformation. If the compression rate is too small, leakage may occur due to the loss of part of the compression due to the coaxiality error of the sealing groove and the O-ring error not meeting the requirements. Therefore, when selecting the compression ratio of the O-ring, various factors must be weighed. Generally, the compression rate of static seals is greater than that of dynamic seals, but its extreme value should be less than 25%. Otherwise, the compressive stress will relax significantly and excessive permanent deformation will occur, which is especially serious in high-temperature conditions.

The selection of compression ratio W of O-type sealing ring should consider the use conditions, static seal or dynamic seal; static seal can be divided into radial seal and axial seal; the leakage gap of radial seal (or cylindrical static seal) is radial Clearance, the leakage clearance of the axial seal (or plane static seal) is the axial clearance. Depending on whether the pressure medium acts on the inner diameter or the outer diameter of the O-ring, the axial seal is divided into two situations: internal pressure and external pressure. The internal pressure increases the stretching, and the external pressure reduces the initial stretching of the O-ring. For the different forms of static seals mentioned above, the sealing medium acts in different directions on the O-ring, so the pre-pressure design is also different. For dynamic seals, it is necessary to distinguish between reciprocating motion seals and rotary motion seals.

1. Static sealing: The cylindrical static sealing device is the same as the reciprocating sealing device, generally taking W=10%~15%; the flat static sealing device takes W=15%~30%.

2. For dynamic seals, it can be divided into three situations; reciprocating motion generally takes W=10% to 15%. The Joule heating effect must be considered when selecting the compression rate for rotary motion seals. Generally speaking, the inner diameter of the O-ring for rotary motion is 3%-5% larger than the shaft diameter, and the compression rate of the outer diameter is W=3%-8%. For O-rings used in low-friction sports, in order to reduce frictional resistance, a smaller compression rate is generally selected, that is, W=5%-8%. In addition, the expansion of the rubber material caused by the medium and temperature must also be taken into consideration. Usually, the maximum allowable expansion rate is 15% outside the given compression deformation. If it exceeds this range, it means that the material selection is inappropriate. O-rings of other materials should be used instead, or the given compression deformation rate should be corrected.

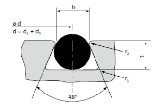

- After the O-ring is installed into the sealing groove, it generally stretches to a certain amount. Like the compression rate, the amount of stretching also has a great impact on the sealing performance and service life of the O-ring. A large amount of stretching will not only make it difficult to install the O-ring, but also reduce the compression rate due to changes in the cross-sectional diameter d0, causing leakage. The stretch amount a can be expressed by the following formula:α=(d+d0)/(d1+d0)

In the formula, d—–shaft diameter (mm); d1—-O-ring inner diameter (mm).

The value range of stretching amount is 1%-5%. As shown in the table, the recommended value for the O-ring stretch amount is given. According to the size of the shaft diameter, the O-ring stretch amount can be selected according to the table. The preferred range of O-ring compression ratio and stretch amount

Seal form Sealing medium Amount of tensionα(%) compressibility w(%) Static seal Hydraulic oil 1.03~1.04 15~25 Air <1.01<span=””> 15~25 Reciprocating motion Hydraulic oil 1.02 12~17 Air <1.01<span=””> 12~17 Rotational motion Hydraulic oil 0.95~1 3~8

- The relationship between the hardness of various O-ring rubber materials and working pressure

Hardness (Shore A)/degree 50±5 60±5 70±5 80±5 90±5 Working pressure static seal/Mpa ≤ 0.5 1 10 20 50 Working pressure (reciprocating motion, reciprocating speed ≤0.2m/s) /Mpa 0.5 1 8 16 24 Note: The working pressure of rotating motion generally does not exceed 0.4Mpa, and the hardness is selected at (70±5) degree: if it exceeds 0.4Mpa, a special sealing device will be set up. Note: The working pressure of rotating motion generally does not exceed 0.4 Mpa, and the hardness is selected at ( 70±5) degree; if it exceeds 0.4Mpa, special sealing device design will be adopted. - Japan JISB 2406-1991 Recommended maximum gap of O-ring seal/mm

Working pressure /MPa Hardness (Shore A)/degree ≤0.4 4.0~6.3 6.3~10 10~16 16~25 70 0.35 0.3 0.15 0.07 0.03 90 0.65 0.6 0.5 0.3 0.17 - U.S. SAEJ120A-1968 recommended maximum O-ring sealing gap value/mm

Hardness (Shore A)/ World working pressure /MPa 70 80 90 0 0.254 0.254 0.254 1.72 0.254 0.254 0.254 3.45 0.203 0.254 0.254 6.89 0.127 0.203 0.254 10.34 0.076 0.127 0.203 13.79 0.102 0.127 20.68 0.076 0.102 34.47 0.076 The relationship between the section diameter of the 0 ring and the speed of the shaft Speed /m/s 0 ring section diameter /mm Speed /m/s 0 ring section diameter /mm 2.03 3.53 7.62 1.78 3.05 2.62 Relationship between hardness and pressure resistance of NBR compound Hardness (Shore A) degree Tensile strength /MPa Elongation /% Applicable pressure normCircumference /MPa 80 22 400 2 85 27 306 20 90 25 120 50 Various groove shapes for mounting 0- rings groove shapes name application

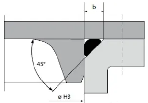

Rectangular groove This is a commonly used groove form suitable for both motion seals and fixed seals.

V-shaped grooves Suitable for fixed seals only. If used as a motion tight cause side friction resistance is very large, easy to squeeze into the gap,

A semicircular groove Can be used for rotary sealing, but generally not used.

Dovetail groove(trapezoidal groove) It is used in occasions where the friction force is very low. Because of the high cost of groove processing, generally not used.

Triangular groove Recommended for fixed sealing applications.