know more about back up ring

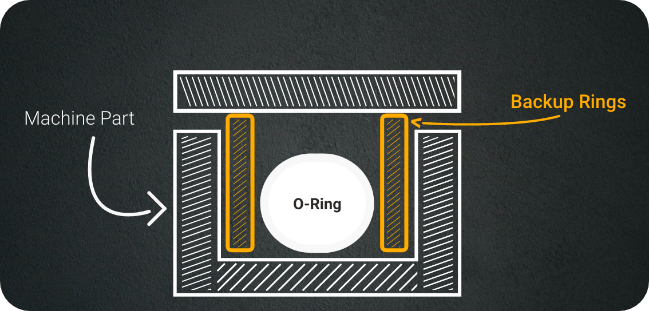

What is the purpose of a back up ring? Backup rings are ultimately used to help stop o ring migration, and they achieve this in both static and dynamic fluid power applications as the pressure cycles occur, preventing the extrusion of an o ring in the gap. Ultimately a backup ring is a rigid ring that…

- What is the purpose of a back up ring?

- What is the difference between o-ring and backup ring?

Backup rings are often installed with rubber O-rings to help improve their performance. These rings are designed to limit O-ring clearance and are used in high pressure sealing situations greater than 1500 PSI. Using these rings prevents O-rings from becoming damaged or pinched, which can cause failure in some systems. Generally speaking, support rings come in two different shapes: flat and concave. The reason for the introduction of the concave support ring is to relieve the stress on the O-ring when it deforms under pressure. However, there is no real performance advantage to flat or concave support rings.

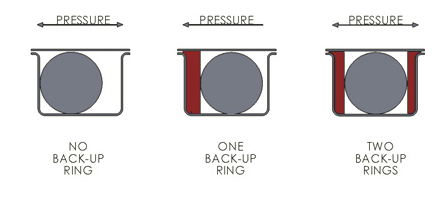

Support rings are used in many different industries around the world. Some typical applications include hydraulic systems, high-pressure hydraulic systems, and high-pressure valves. In most applications, it is usually best to use two backup rings, one above and one below the O-ring. This application will provide optimal support for the O-ring and allow for smooth operation.

Spare rings are required in the following applications:

• O-rings have low durability

The unfavorable mechanical environment is inherent

• Dynamic applications over 100bar

• Static application around 950bar

• Hydraulic cylinder

• High pressure hydraulic system

• High pressure valve

Specification:

When choosing the right support ring for your application, it’s important to understand the most important specifications:

• Internal dimensions of the ring or external dimensions of the shaft

• Radial cross-section of elastomer

• Ring thickness

Using a back-up ring may be a practical solution, plugging the diameter gap and providing support for the O-ring when the stress on the O-ring increases to the point where it can no longer withstand being squeezed into the diameter gap.

Backup rings are made of a stronger, stiffer material than O-rings. However, it is still elastic enough to deform under stress to close the squeeze gap. The O-ring grooves are enlarged to accommodate the use of backup rings.

Many materials are available for support rings, such as PTFE, metal, or hard rubber. PTFE has the advantage of extremely low friction in dynamic applications.

Our Backup Ring Production Line

This video demonstrates the cutting of the backup ring