Research on sustainable design of Rotary Shaft Lip Seal

Rotary shaft lip seal (referred to as oil seal) is a contact rotary seal form, which is a key basic component to ensure the safety, reliability, longevity and fate of machinery and equipment in the fields of machinery, automotive, aerospace, shipbuilding and national defense. The rotary shaft lip seal in all stages of its life…

Rotary shaft lip seal (referred to as oil seal) is a contact rotary seal form, which is a key basic component to ensure the safety, reliability, longevity and fate of machinery and equipment in the fields of machinery, automotive, aerospace, shipbuilding and national defense.

The rotary shaft lip seal in all stages of its life cycle, such as the mining and production of sealing materials, sealing forming and processing, transportation, use, recycling will have an impact on the environment, such as the use of sealing leakage caused by the waste of sealing media and environmental pollution, the friction loss between the seal and the shaft shortens the service life of the seal, increasing the time of disassembly and maintenance The cost reduces the energy efficiency of the host. For this reason, researchers focused on the safety, reliability and integrity of the use of the rotary shaft lip seal. In terms of energy saving of the rotary shaft lip seal,BOCK et al. designed a low-friction engine seal structure that reduces energy consumption; MAREK explored ways to reduce oil seal energy consumption from several aspects, such as the structural shape of the rotary shaft lip seal, the material of the seal, the characteristics of the lubricating oil, the material of the rotary shaft and the machining roughness. Zhang Siwei summarized the latest development achievements in the field of green tribology from the aspects of tribology energy saving, emission reduction, ultra-low friction and wear, application of ecological tribology materials and technology, tribology technology of clean energy equipment, etc. During sealing operation, lubrication, wear and friction between sealing interfaces are typical tribology categories, so the sustainability of sealing is an inevitable requirement for the development of green tribology.

In the 21st century, the resource crisis and the increasingly strict environmental regulations have put forward new challenges to the lip seal, such as intelligence, integration, green environmental protection, energy efficiency and high reliability.

1. Structural composition of oil seal and its production process

- The structure and material composition of the product have an important impact on the sustainability of its production and processing stage. In order to facilitate the sustainability analysis of the oil seal, it is necessary to first determine its structural form, basic composition, working parameters and material characteristics.

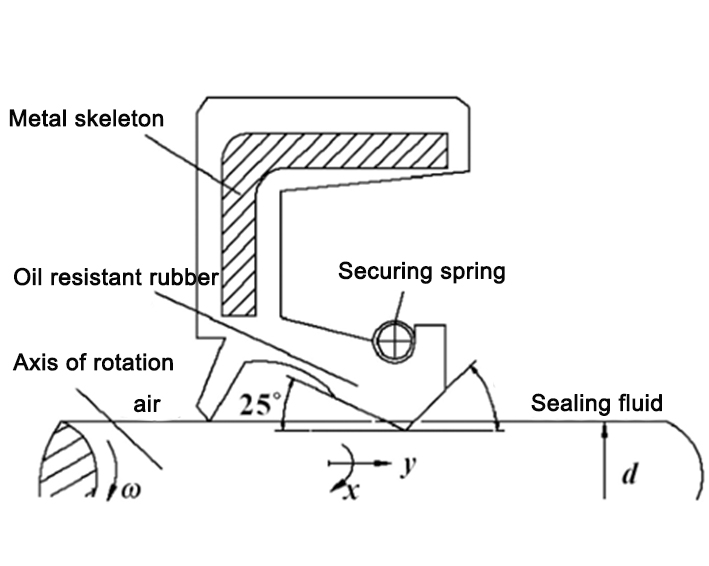

- For example, the TC type oil seal size is 60 mm×80 mm×8 mm, which is used to seal the gear shaft bearing of a reducer. The oil seal is an inner frame structure with a dust-proof secondary lip, which is composed of an elastomer sealing element (lip material), a metal frame and a tightening spring. The lip of the rotary shaft lip seal, the rotary shaft and the sealing medium with interference, together form the sealing and friction system of the oil seal.

- The oil seal is sealed by the radial force exerted by the lip of the elastic sealing element. The material of the elastic sealing element is oil-resistant rubber material, such as nitrile butadiene rubber (NBR), hydrogenated nitrile butadiene rubber (HNBR), fluorine rubber (FKM), etc. The superelastic characteristics of rubber 1 material can reduce the influence of adverse factors such as vibration and eccentricity of the rotating shaft, and has good following performance and compensation. The skeleton is embedded in the rubber body, which plays the role of positioning and support, and its material is generally made of 08F steel plate, which can be made of stainless steel when the seal has corrosive media; The fastening spring is used to provide a constant radial force to the seal lip, and its material is usually spring wire or stainless steel wire.

Structure and quality of oil seal

| No. | Name | QTY | Material | Weight m/g |

| 1 | Elastic element | 1 | NBR | 6.14 |

| 2 | skeleton | 1 | 08F steel | 22.9 |

| 3 | Securing spring | 1 | Piano wire | 5.02 |

| Gross mass | 34.06 | |||

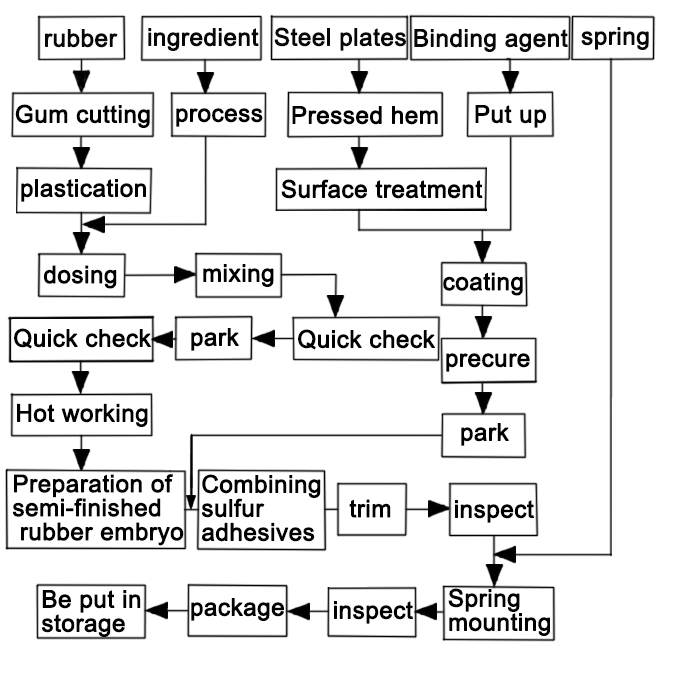

- Different structural forms of oil seals lead to the diversification of its processing technology and equipment tooling, with the enhancement of environmental legislation and people’s environmental awareness, the efficiency of the rotary shaft lip seal production process, material saving, consumption reduction, emission reduction, has become the main development trend in the future.The processing process of oil seal mainly includes rubber material manufacturing, semi-finished product processing, vulcanization molding, spring installation, etc. Different process methods will have a great difference in the impact on the environment and the labor intensity of operators. For example, in the rubber mixing equipment, equipped with automatic batching and mixing process automatic control of the mixer system, molding process, the application of efficient, advanced, high-quality rubber injection molding processing technology, can effectively achieve energy saving and efficient oil seal production, reduce environmental pollution.

The oil seal production process is shown in Figure blow. First of all, it is necessary to complete the production of elastomer, metal skeleton processing, fastening spring production, and then the elastomer and the skeleton using adhesive bond after installing the clamping spring. The production of elastomer includes the mixing of rubber material and the manufacture of semi-finished rubber material; The processing of the skeleton is generally processed by punching machine or lathe; The production of the clamping spring includes winding, low temperature annealing, cutting and end to end joining.

2.Sustainable analysis of oil seal

2.Sustainable analysis of oil seal

- The whole life cycle of oil seal includes several stages of raw material acquisition, processing and production, transportation, use and recycling.According to the type, structure, material and quality of the oil seal studied in this paper, the equipment used in the production stage of the oil seal is a single knife oil pressure rubber cutting machine, XK-400 plasticizer, rubber extruder, semi-automatic spring loading machine .The life cycle cost of oil seal includes manufacturing cost, use cost and maintenance cost. The processing and production cost of oil seal is low, and the maintenance cost when the oil seal is damaged accounts for several times of the cost of oil seal. Therefore, increasing the service life of oil seals is an important way to improve the economic sustainability of oil seals.It is very necessary to choose good quality oil seal products.

3.Sustainable design of oil seals

- Seal life, energy consumption and carbon emissions during operation reflect the environmental sustainability of the oil seal during its use. The sealing life refers to the ability of the seal to maintain the sealing performance for a long time, which is the basic requirement for the seal. Extending the service life of the oil seal can reduce the number of oil seal replacements, reduce the cost, reduce the utilization of raw materials, reduce the energy consumption and carbon emissions of the oil seal production process, and thus improve the economic and environmental sustainability of the oil seal. Maintaining a constant sealing capacity can also reduce the leakage of harmful sealing media to the environment and operator harm, improve social sustainability.

- The energy consumption of oil seal during operation refers to the friction loss of oil seal during operation. High energy consumption, high heat output when the oil seal is working, and the temperature of the sealing interface increases, which will cause the aging of the oil seal material, the carbon deposition of the sealing lip and the deterioration of the lubricating oil performance, and reduce the service life and sealing capacity of the oil seal.

- Wear is one of the main causes of low seal life, because the wear of the oil seal causes the loss of lip material, changes the contact pressure between the sealing interfaces, and ultimately leads to a reduction in sealing capacity.

- The wear of the oil seal is related to the material hardness of the oil seal, the radial load of the lip and the rotational speed. The radial load is formed by the dynamic oil film pressure and rough peak contact. Therefore, under the condition of a certain working speed, the wear resistance of the oil seal can be improved by reducing the radial load, increasing the hardness of the material and improving the lubrication state of the sealing area.

- The friction state of the oil seal during operation depends on the thickness of the film between the sealing interfaces . When the dimensions-one film thickness is less than 3, the seal is in a mixed lubrication state, rough peak contact and fluid film exist simultaneously, and the friction torque is composed of rough peak shear friction torque and fluid film viscous friction torque. When the thickness of dimension one film is greater than 3, the sealing interface is in the state of fluid lubrication, and the friction torque is generated by the viscous shear friction of the fluid film, and the friction torque is lower than that in the mixed friction state.

- Therefore, maintaining a stable lubricating oil film is the key to reducing wear and friction.The distribution and shape of the lubricating oil film are closely related to the macroscopic cross-section shape of the oil seal and the microscopic surface morphology of the sealing area. The macroscopic geometry and size of oil seal determine the radial force of oil seal. However, the microscopic surface morphology affects the contact width between the seal lip and the shaft, the contact pressure distribution between the seal interface and the lubrication state of the seal area.Therefore, the sustainable improvement design of the oil seal is essentially through the macro and micro shape design of the oil seal, so that the oil film thickness is in the optimal state.